HTC 200 II 560

HTC II series CNC lathes, fully fit the needs of users, focusing on the function characteristics of high precision, high efficiency and high stability. The series is equipped with Haitian self-developed built-in spindle and servo power turret, the machine can cover φ 300-φ 520 processing diameter specifications, widely used in automotive parts, aerospace and general parts industry. Especially suitable for precision machining of small diameter and short shaft products.

The new generation HTC II series CNC lathe adopts the whole casting bed structure, reasonable reinforcement cavity layout, through the finite element analysis, minimizes the vibration, distortion and thermal deformation, with good thermal stability and long-term accuracy retention.

Standard Configuration Price $99,000 or $3,506/ Month

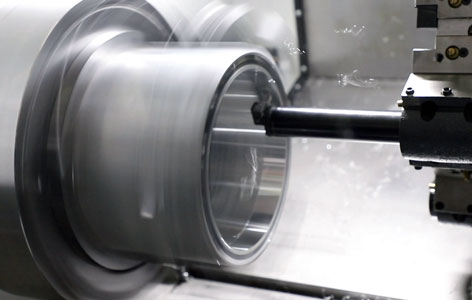

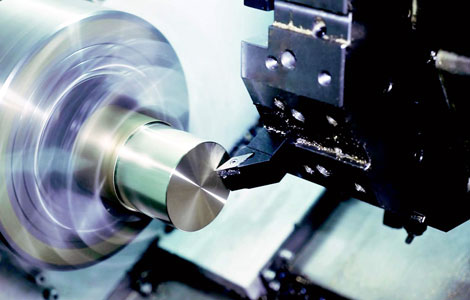

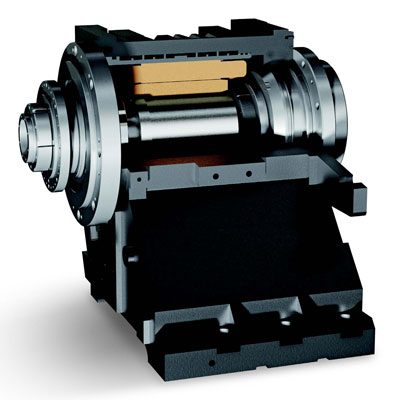

Full Range Built-In Spindle

- The spindle is driven directly by the built-in motor, without the use of additional transmission links allowing for zero transmission of the machine tool and enhanced reliability.

- Static and dynamic high precision allowing for optimal stability.

- Motorized spindle speed up and down, short start and stop time, improve production efficiency.

- State of the art design allows for exceptional torque and speed performance.

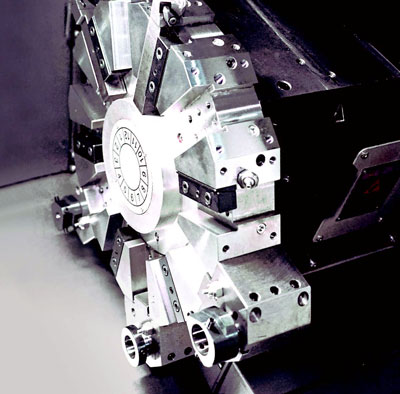

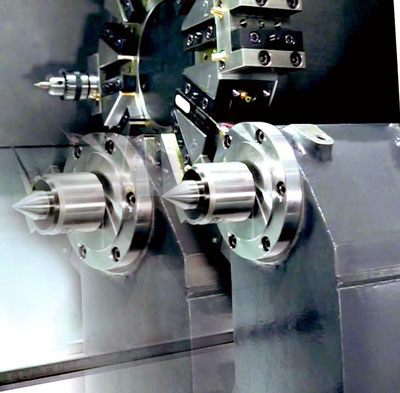

Full Series Servo Turret (Optional power turret)

The HTC II series lathes can be equipped with a servo enabled turret, which provides exceptional positioning and a reliable transmission link. Additionally, the servo enabled turret realizes synchronous tool changes for improved production efficiency.

Servo Tailstock (Option)

Utilization of servo motor control provides quick response and accurate positioning. This enhanced feature allows for ease during automation, as well.

Chip Removal and Processing

The HTC II series allows for a rear chip removal mode. Additionally, the machine’s compact structure provides a small footprint, suitable for automatic processing.

Automatic Protection Module

An available automatic door with skylight modular design provides for additional convenience during operation.

HTC 200 II 560

| Items | Unit | HTC200 II X 560 |

| » Working Area | ||

| Max. swing over bed | mm | Φ620 |

| Max. swing over saddle | mm | Φ410 |

| Max. turning diameter | mm | Φ400 |

| Max. turning length | mm | 560 |

| Spindle center to ground | mm | 1035 |

| » High Speed Motorized Spindle | ||

| Max. spindle speed | rpm | 4500 |

| Spindle power (continuous/30min overload) |

kW | 15/22 (OP FANUC 11/15) |

| Spindle torque | Nm | 159/252 (OP FANUC 158/211) |

| Spindle nose taper | - | JISA2-6 |

| Spindle through hole | mm | Φ66 |

| Spindle bearing diameter | mm | Φ100 |

| Chuck size | inch | 8 |

| » Turret | ||

| Type | - | Servo V12 |

| OD tool size | mm | 25x25 |

| Max. boring bar size | mm | Φ40 |

| » Tailstock | ||

| Tailstock type | - | Hydraulic |

| Tailstock travel | mm | 550 |

| Quill taper | - | MT.NO.5 |

| » Feed Shaft | ||

| X/Z axis travel | mm | 215/615 |

| Rapid feed X/Z axis | m/min | 24/30 |

| Guideway type | - | Linear guideway |

| X/Z axis power | kW | 2.2/2.2 (OP FANUC 1.8/1.8) |

| » Others | ||

| Power capacity | kVA | 35 |

| Machine size (LxWxH) (without conveyor) | cm | 310x185x175 |

| Machine weight | t | 4.8 |

Standard Configuration

- Controller: Fanuc 0i / SIEMENS 828D

- Cutting cooling

- Full enclosure

- Servo turret

- Soild hydraulic chuck

- Hydraulic tailstock with live center (without HTC150Ⅱ&HTC200Ⅱ×360)

- Tool holder

- External chain type chip conveyor (rear)

- Standard accessories

- Common maintenance tool

- Soft jaw

- 3-Color signal lamp, working light

- Foot switch

- Trolley