Vertical Machining Centers

HI-M SERIES

HIM-G1/G2+ delivers high-speed, high-precision machining for dry cutting of graphite electrodes used in the aluminum die casting process.

HIREX SERIES

High efficiency traveling column machining center.

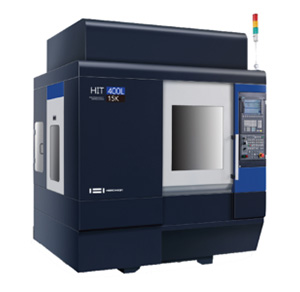

HIT SERIES

HIT-Series uses direct high speed spindles which enable stable rigid tapping and drilling during prolonged machining. It's quick tool change and fast feed minimize non-cutting time to yield high productivity. This high-speed Tapping Center delivers excellent performance especially in IT component and auto part machining.

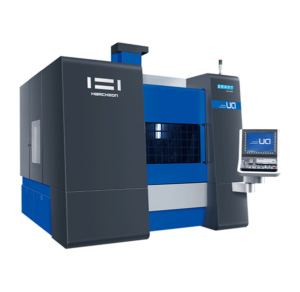

SIRIUS-UX SERIES

Ideal for high-quality die and mold manufacturing, SIRIUS-UX vertical machinging center gives you a total solution from tool selection to product completion.

SMART SERIES

The SMART auto machining center realizes high productivity through the best automation technology. Automatically, the machine generates the optimal NC data and sets the size of the workpiece location on the table when an operator selects a CAD model.

SIRIUS SERIES

Vertical machining centers with gear box spindle and box way design.

SIRIUS-UL+ SERIES

SIRIUS-UL+ is a vertical die and mold center whose performance is world-leading. It provides your company with a total one stop production solution, from tool selection to final product.

VESTA SERIES

The VESTA series of machining centers are optimized for job shop machining applications, with the easy-to-use interface to maximize your productivity.

D - Series

Universal 5 or 4+1 axis machining centre for mechanical machining

The compact machining centres in the D series are ideal for use in workshops, education and laboratories as well for as tool, jig, die and mould making. As standard, the machines have 5 axes, of which 4 can be simultaneously controlled. Optionally all 5 axes can also be controlled simultaneously. The stability, high accuracy and high drive power derive from heavy machine beds, spindles made by Hwacheon and the use of high quality components. A large selection of Hwacheon spindles is available for each field of application.

D2-5AX

Universal 5-axis machining centre with Ø600 mm - rotary table

The compact D2-5AX is designed for use in workshops, education, laboratories and for tool, jig, die and mould making. The D2-5AX has 5 axes as standard, of which 4 can be controlled simultaneously.

D3-5AX

Universal 5-axis machining center with table size 0800 mm

The D3-5AX is predestined for use in the workshop, training, laboratory as well as tool, jig and mold making. As standard, the D3-5AX has 5 axes, 4 of which can be controlled simultaneously.

M - Series

Extremely robust 5-axis simultaneous milling machine for workpieces of up to 1.2 t

The gantry-based construction and rotary table allow the M series to reach rapid traverse speeds of up to 50 m/min. Three types, with table sizes of D500, D700 and D800 are available. The M3 and M4 models allow dynamic table movements on the Y axis and have twin drives which can accept workpiece weights of up to 1.2 t.

M1-5AX

5-axis machining centre with Ø300 mm rotary table

The M1-5AX now complements the M series with a model with a 300 mm rotary table for small workpiece sizes.

M2-5AX

5-axis machining centre with Ø500 mm rotary table

The M2 sets new standards for tool, die and mould making applications and precision parts.

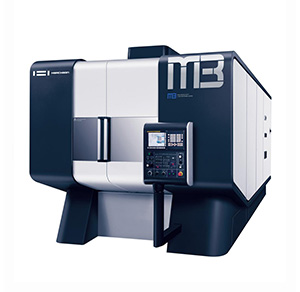

M3-5AX

5-axis machining centre with Ø700 mm rotary table (800 kg)

For applications in tool, die and mould making, from precision components to heavy duty cutting, the M3 sets a new standard.

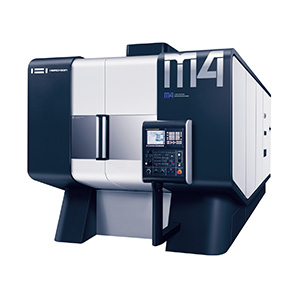

M4-5AX

5-axis machining centre with Ø800 x 630 mm table (1,2 tons)

For applications in tool, die and mould making, from precision components to heavy duty cutting, the M4 sets a new standard.